Your specialist for

leak testing and automation

Please note:

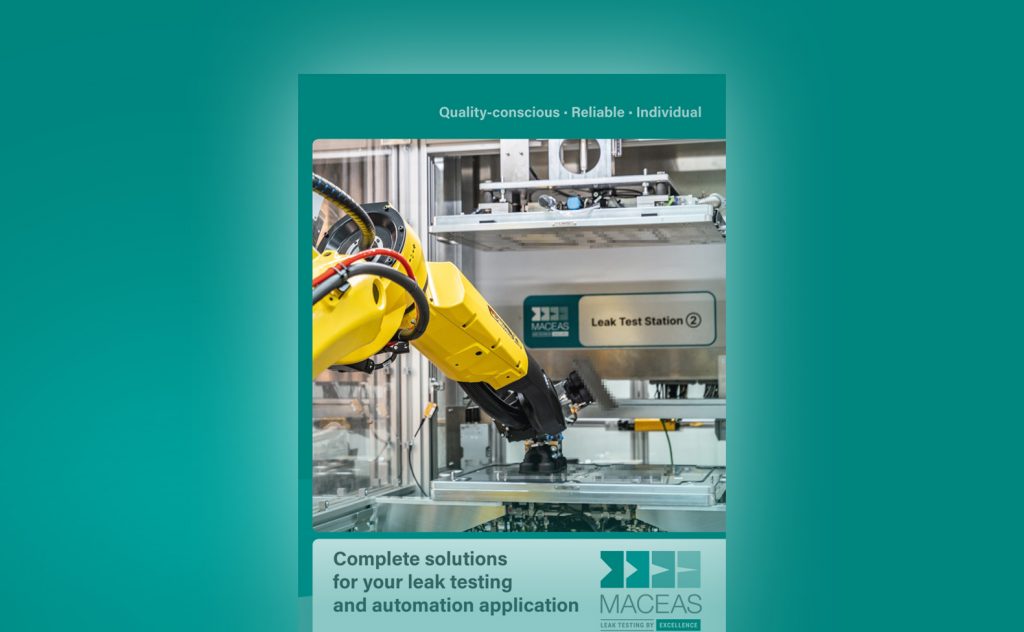

We offer our customers individual overall solutions in the field of leak testing and automation. Our core competencies are helium leak testing and ultrasonic gas bubble detection in a water bath in combination with tailor-made automation solutions. We are therefore part of the quality control and ensure that the industrial series production runs smoothly.

News

Find out all the news about Worthmann & MACEAS products from the world of automated leak testing and measuring systems, commissioning of new helium or even ultrasonic leak testers or the latest company news. Have fun browsing!

We are pleased to announce that MACEAS are now collaborating with SP Leak Test & Automation Pvt. Ltd. in Bangalore, …

We present the 4th generation of a pioneering technology in the field of industrial leak testing: ultrasonic gas bubble detection …

📍 Messe Stuttgart | 📅 June 03-05 | Hall 4, Stand D21 We are delighted to be part of The …

MACEAS is pleased to announce its third participation in the H2&FC Expo, which will be held in Tokyo from February …

For the first time, MACEAS is taking part in the Future Battery Forum in Berlin. From November 05 – 06, …

The Hydrogen Technology Expo Europe is the must-attend conference and exhibition that is exclusively dedicated to discussing advanced technologies for …

From June 26 – 27, 2024, MACEAS will be exhibiting for the first time in North America. We are part …

Next week from June 18-20, 2024, the battery and H/EV industry will meet in Stuttgart. More than 1,100 exhibitors will …

MACEAS will once again be taking part in the Hydrogen Online Workshop in 2024. However, this year it will be …

MACEAS is expanding its international network and will be represented by new partners in several countries in the future. These …

Helium Leak Testing

The helium leak test is a fast and process-reliable semi or fully automatic test method that can be used for reliably detection and localization of even very small leaks. And that both in the laboratory and in large-volume series production.

Ultrasonic Leak Testing

The universally applicable ultrasonic leak test is the new dimension of gas bubble detection in the water bath. This is an objective, worker-independent, semi or fully automatic leak test method for industrial series production. A particular advantage is that the leakage points can also be automatically localized very precisely.

Hydrogen Solutions

Hydrogen is an important component of the energy and mobility transition. We already offer innovative and reliable leak tests for fuel cell bipolar plates. Leak testing of hydrogen pressure vessels and cryogenic hydrogen tanks is just part of our product portfolio in the emerging hydrogen technology.

Battery Solutions

High demands are made on the battery cell as well as the battery modules and packs in terms of quality, safety, reliability and durability. The leak tightness of the components also plays a crucial role as a decisive quality feature. Our leak testing systems enable the detection of very small leaks, even in the end-of-line testing of sealed battery cells.

Automation and special machine construction

As a special purpose machinery manufacturer and system integrator, we can provide our customers with a competent and tailor-made solution from a single source, from the planning to the production-ready series system, with different degrees of automation.

Career

Shaping the future and working on the technologies of tomorrow?WORTHMANN mechanical engineering is looking for motivated and committed colleagues.