Detect and localize leaks with an ultrasonic leak tester up to 10–5 mbar · l/s

The ultrasonic leak test is the logical further development of the so-called “bicycle tube” method – you are certainly familiar with it. Your bike has a “flat tire”. Now it is time to remove the defective tube, inflate it, hold it under water and analyze where the air bubbles are coming up. This method comes pretty close to the actual ultrasonic leak test. What is hopefully only rarely necessary with your own bike, happens millions of times every day in industrial series production. An infinite number of products have to be leak tight and are tested using the “bicycle tube” method, for example in the automotive industry (fuel tanks, petrol or brake lines, pump housing, etc.) or in the building sector (gas meters, radiators, water taps, etc.).

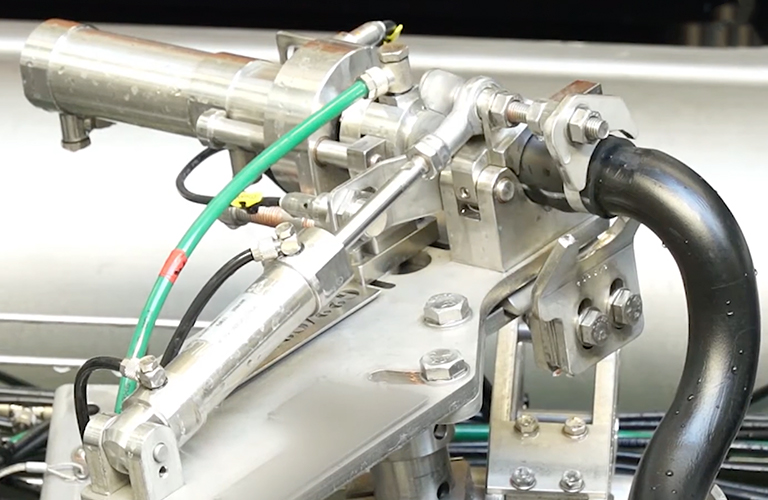

By using our ultrasonic leak test, the formerly worker-dependent water bath test becomes an objective semi- or fully automatic ultrasonic leak test system. In addition, it is possible to use ultrasonic leak testing not only to detect a leak, but also to localize it. Furthermore, this can be implemented up to a leakage rate of 10–5 mbar ⋅ l/s. Therefore, the ultrasonic leak test can be used for various components. In addition, this test can be operated universally and can be applied in industrial series production in various sectors.

Your benefits at a glance:

- Objective and transparent leak test

- Testing of several parts in one basin possible

- Direct localizing measurement method

- Low test gas costs due to the test gas air

- Semi- or fully automated system

- Maintenance-free ultrasound system

- No periodic calibration required

- No vacuum components

- Low operating costs

- Article fixtures for other product variants

Areas of application

Further information on ultrasonic leak testing

Reliable localization and detection of leaks

With ultrasonic leak testing, leaks can not only be detected, but also localized using an optional ultrasonic bubble detection system. This method is more reliable than the worker water bath test (the so-called underwater visual test), as even the smallest air bubbles can be detected and localized by the ultrasonic bubble detection system, which are barely visible to the human eye, if at all.